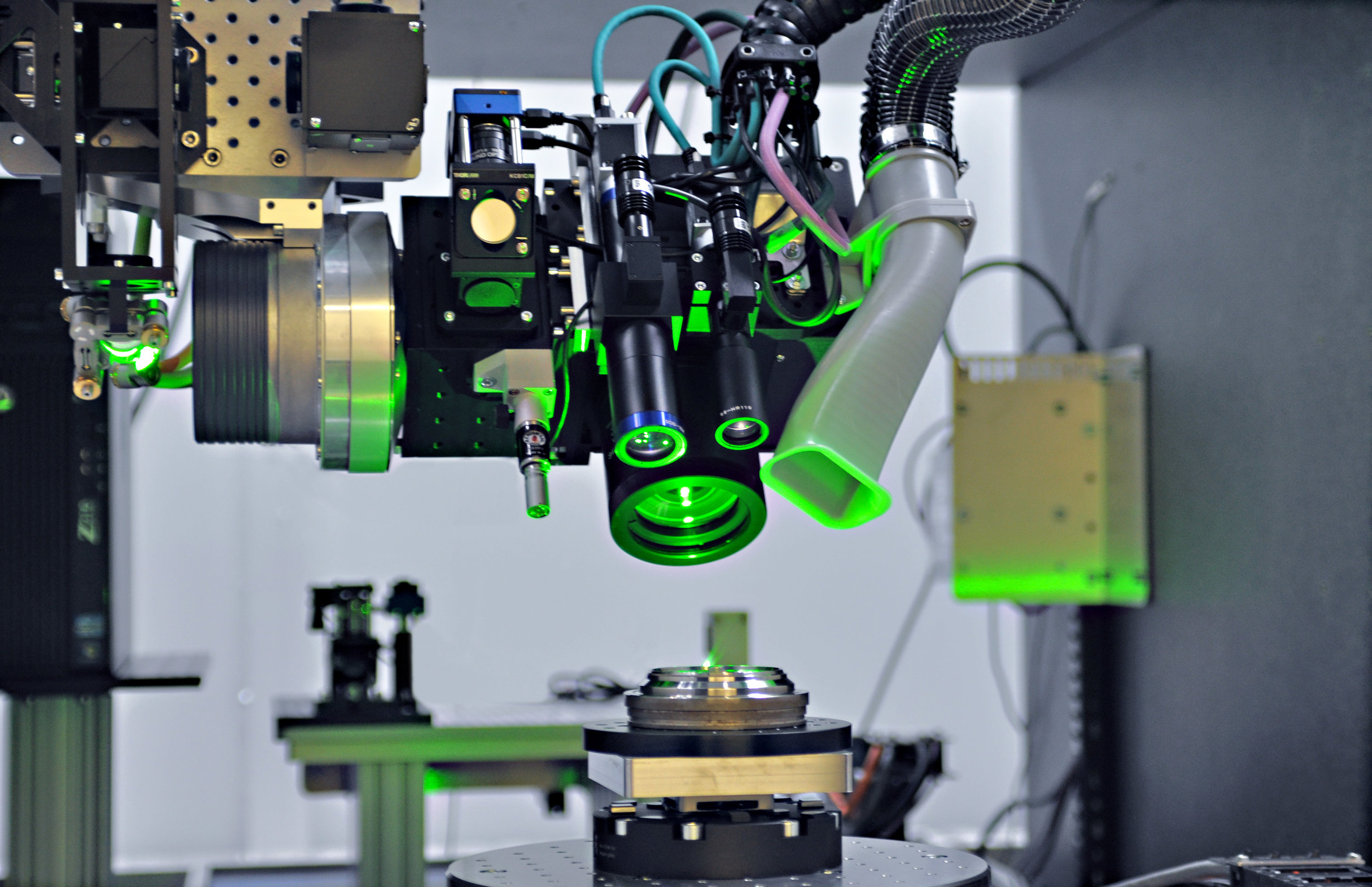

Ultrashort pulse laser ablation is a highly accurate laser micromachining method and is capable of machining any material with minimal damage. The unmatched versatility of this new production tool enables manufacturing of improved products or products with new functionality.

Lightmotif is an innovative supplier of ultrashort pulse laser micromachining systems and processes. We support customers from idea to production, offering solutions for every stage: process/application development, contract manufacturing, and standard or custom high-end laser machines.

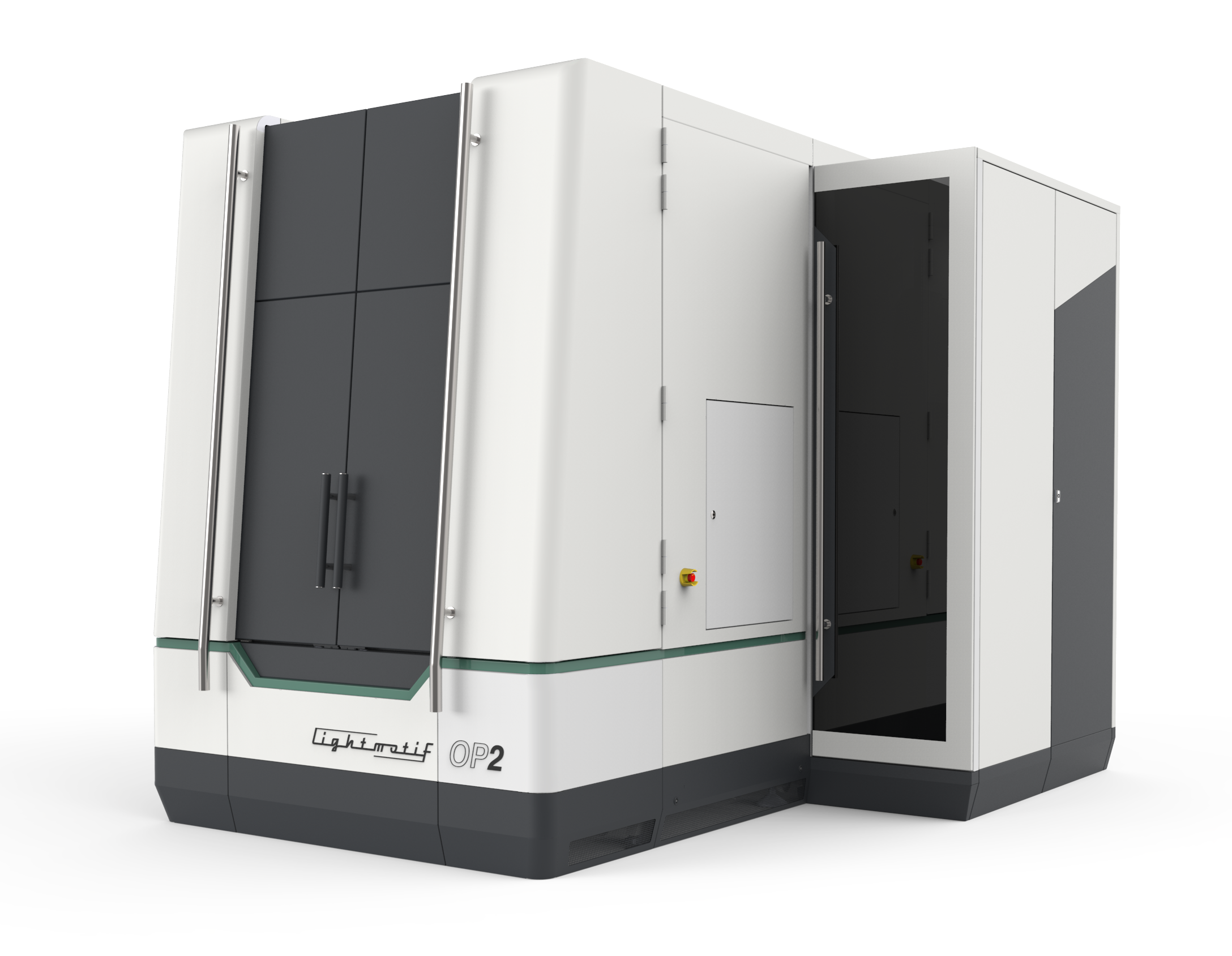

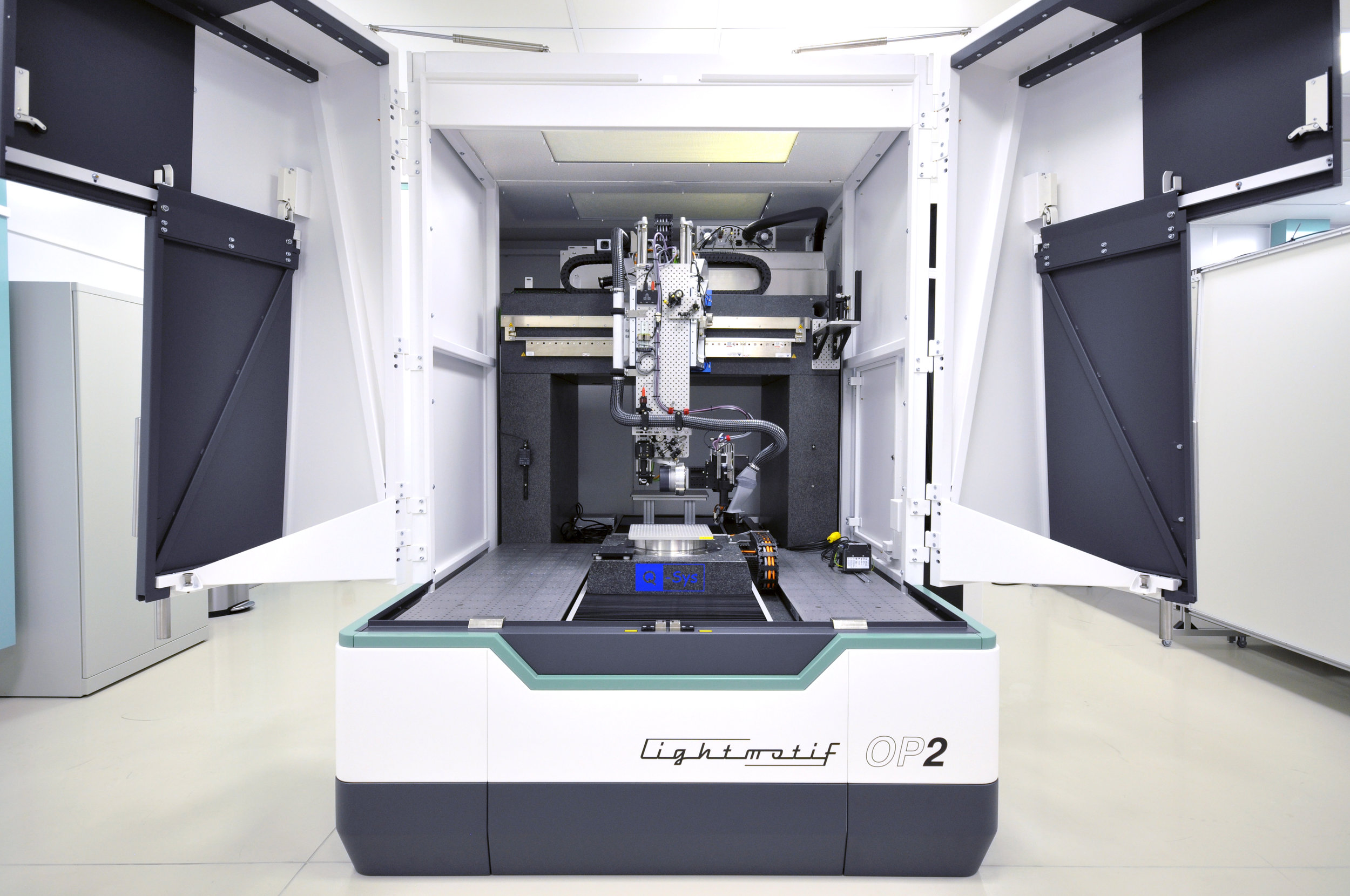

Systems

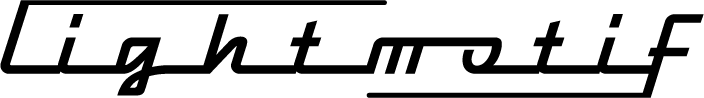

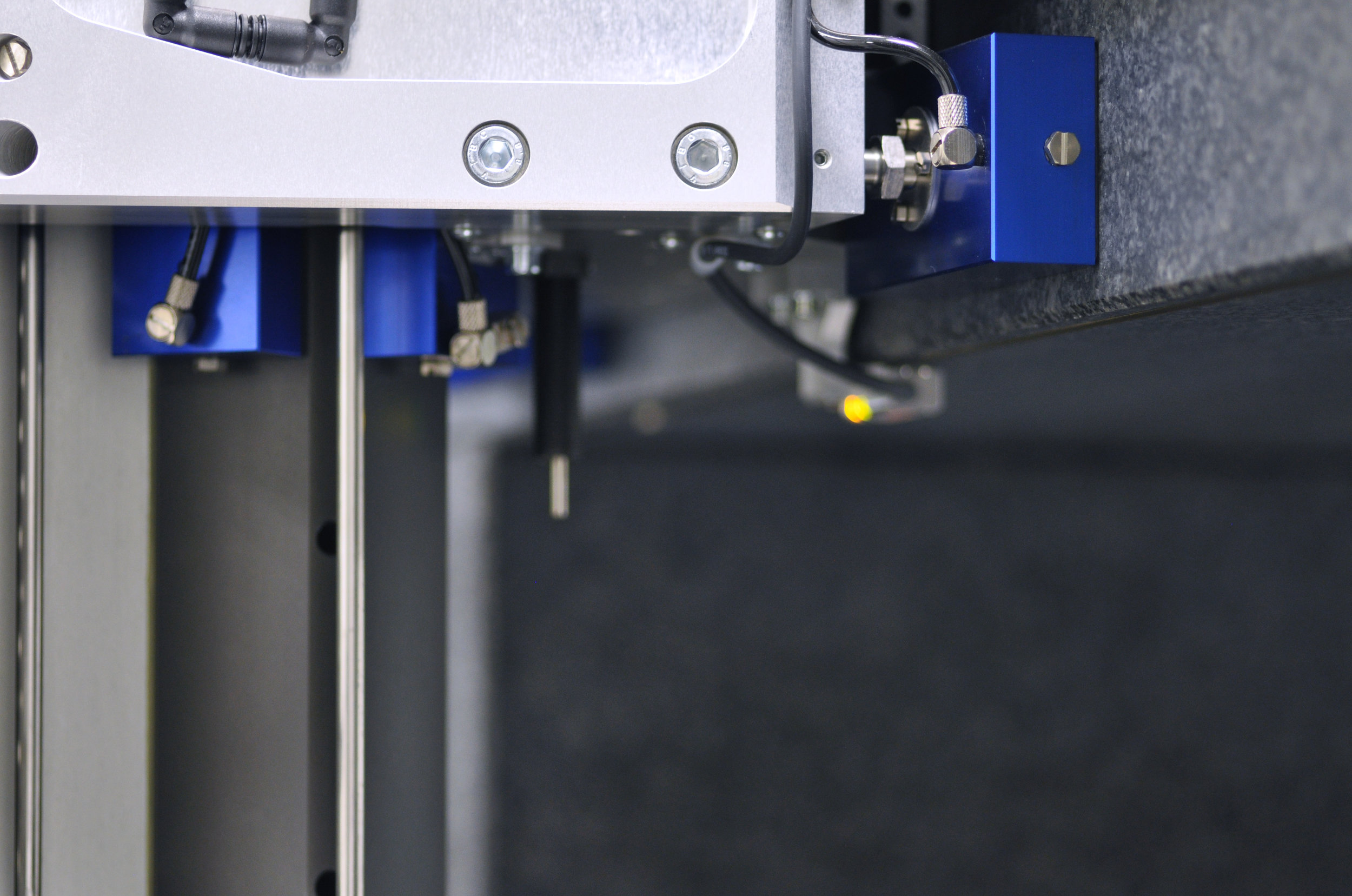

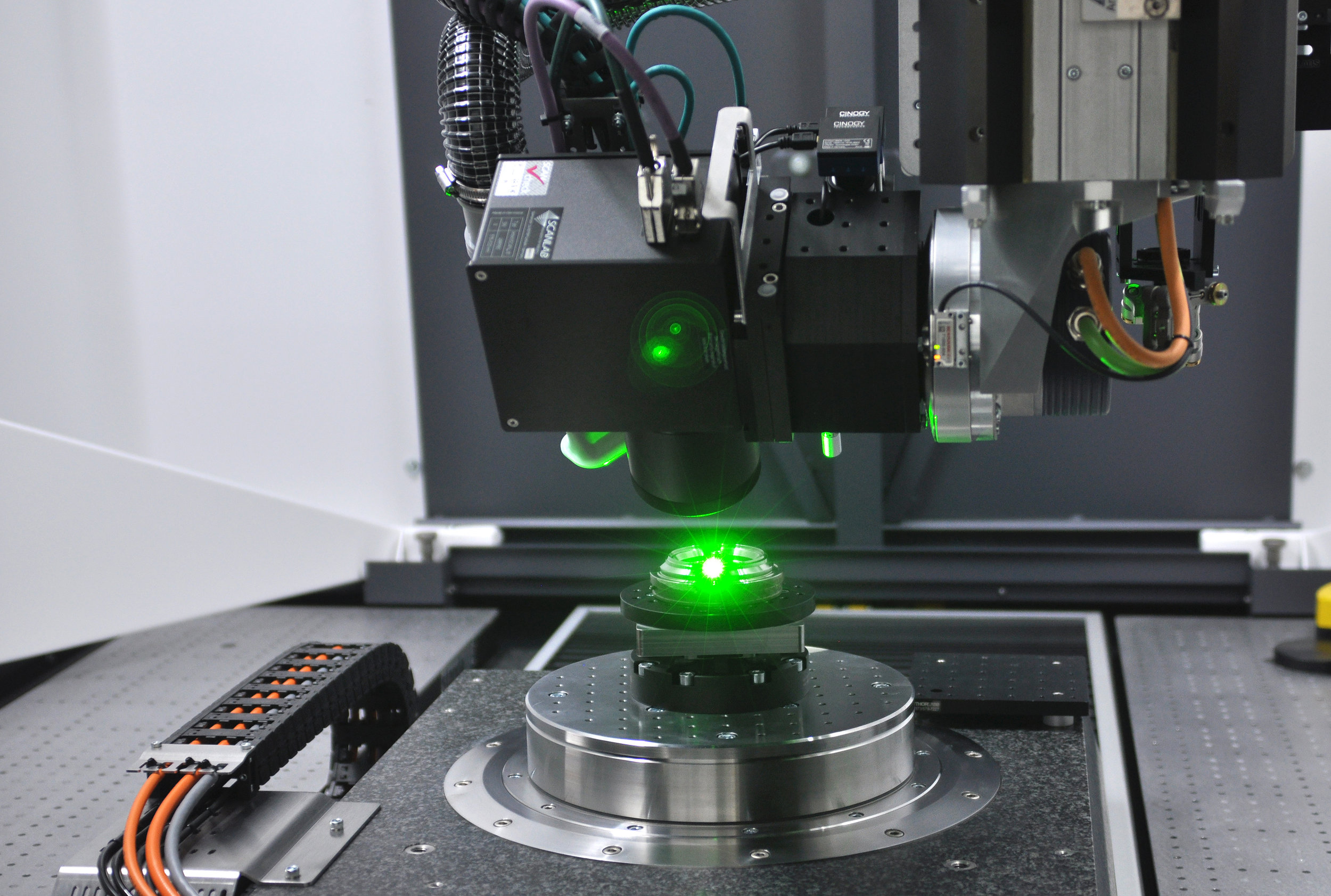

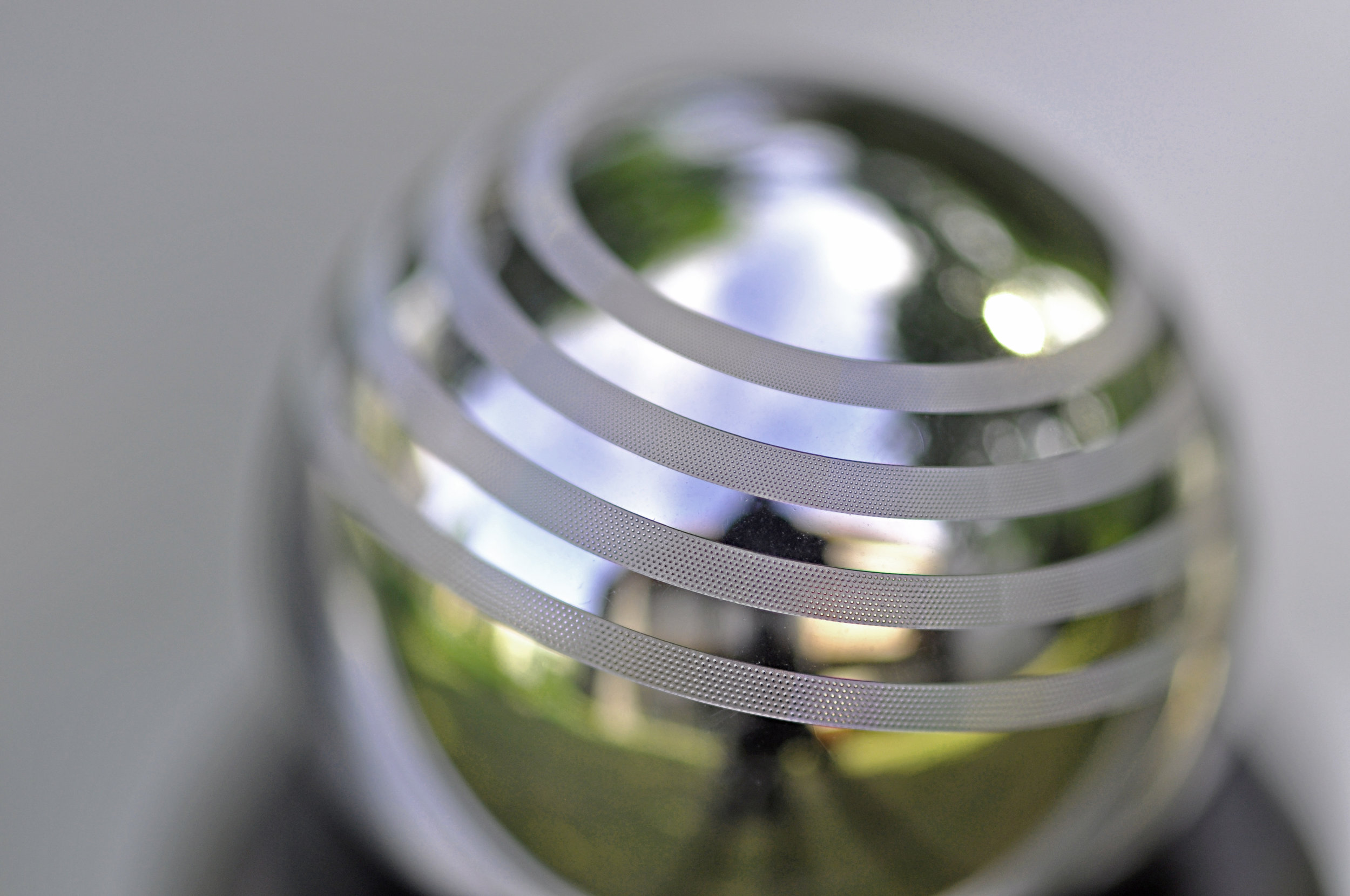

Through our partner Kern Microtechnik, a leader in precision machine tools, we offer the highly accurate Kern Femto E3 and E5 laser micromachining systems, designed for exceptional results on small to medium-sized parts. We can also provide semi-custom machines—based on a modular reference platform—tailored to specific customer requirements.

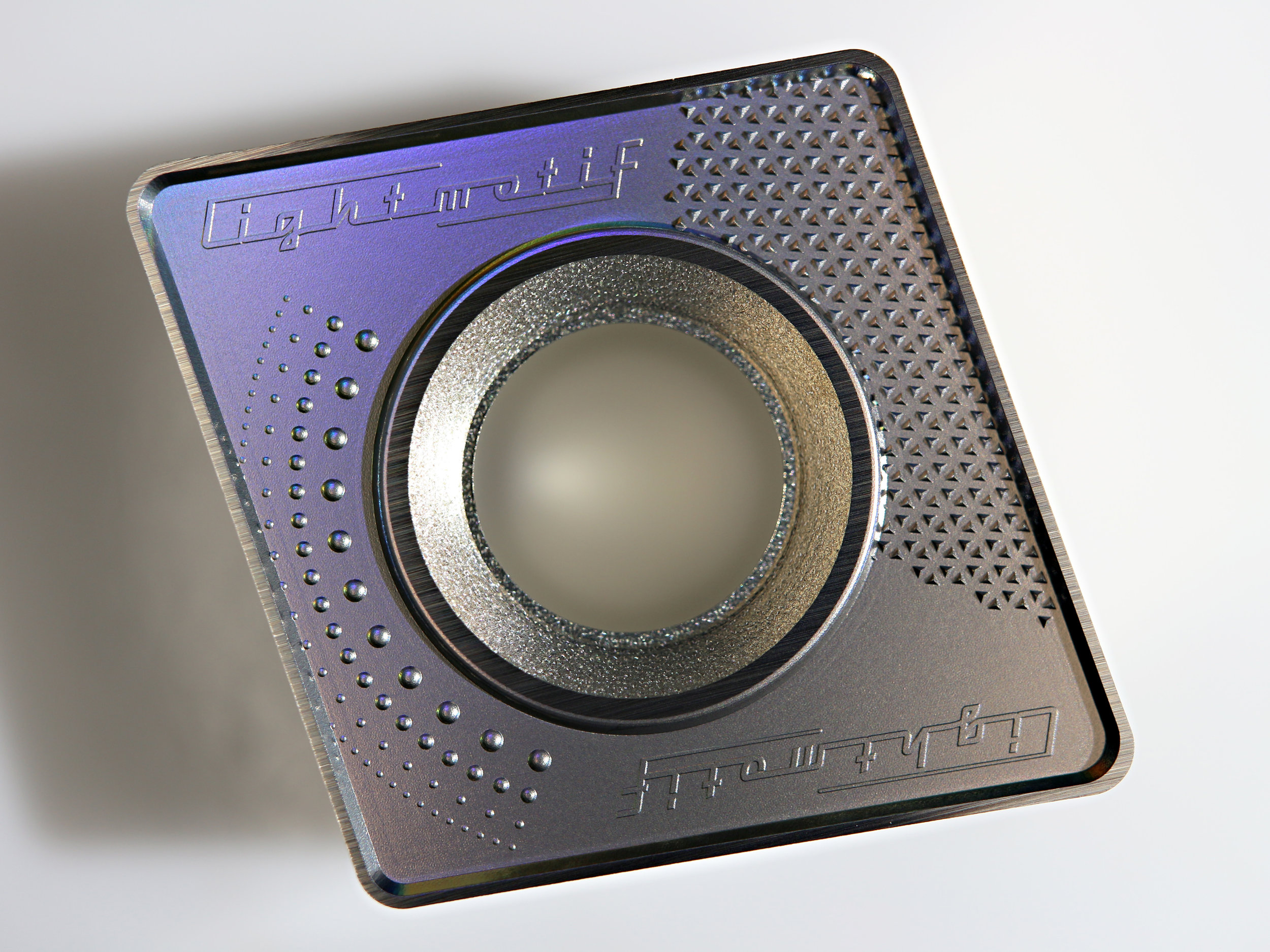

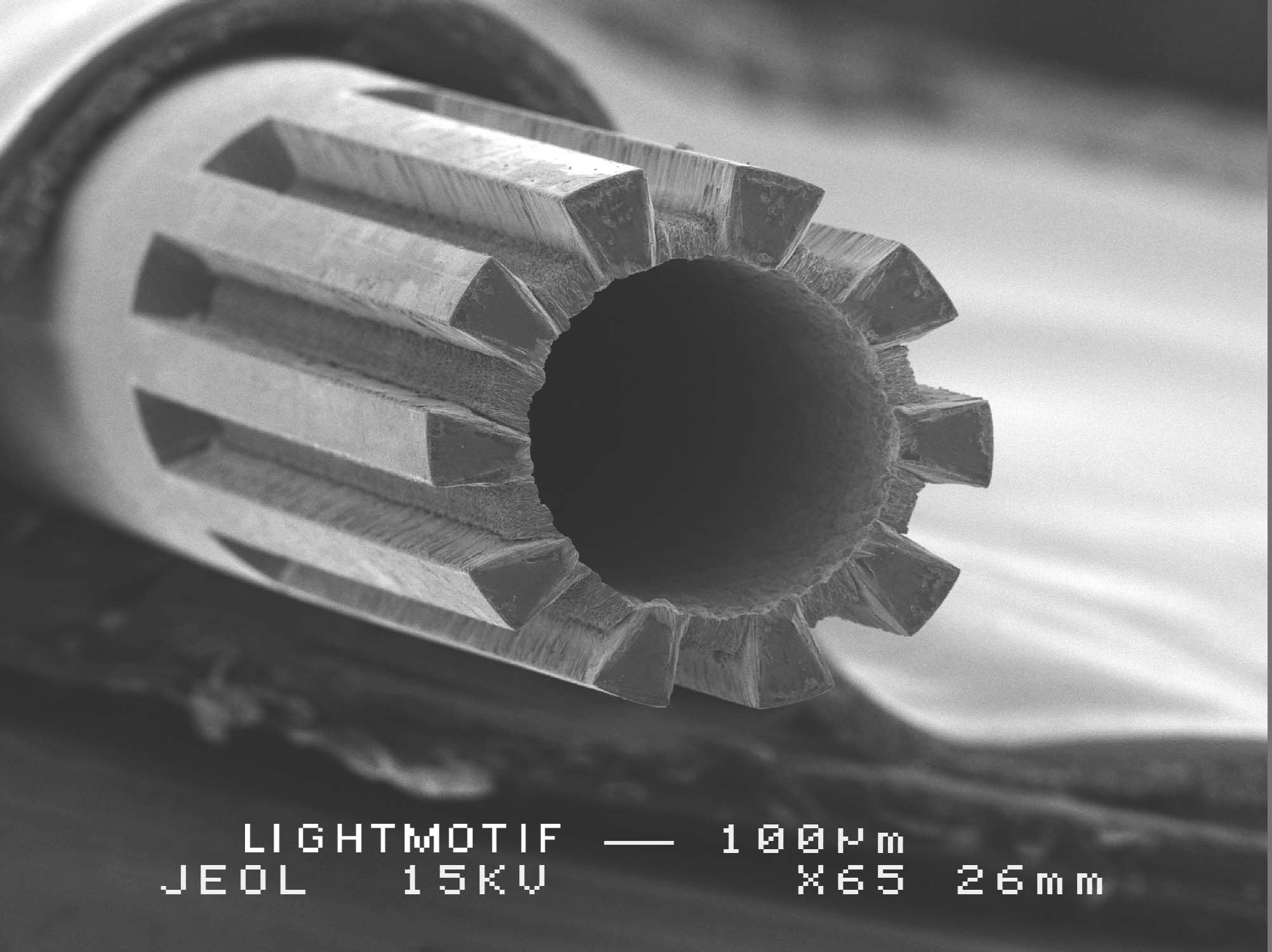

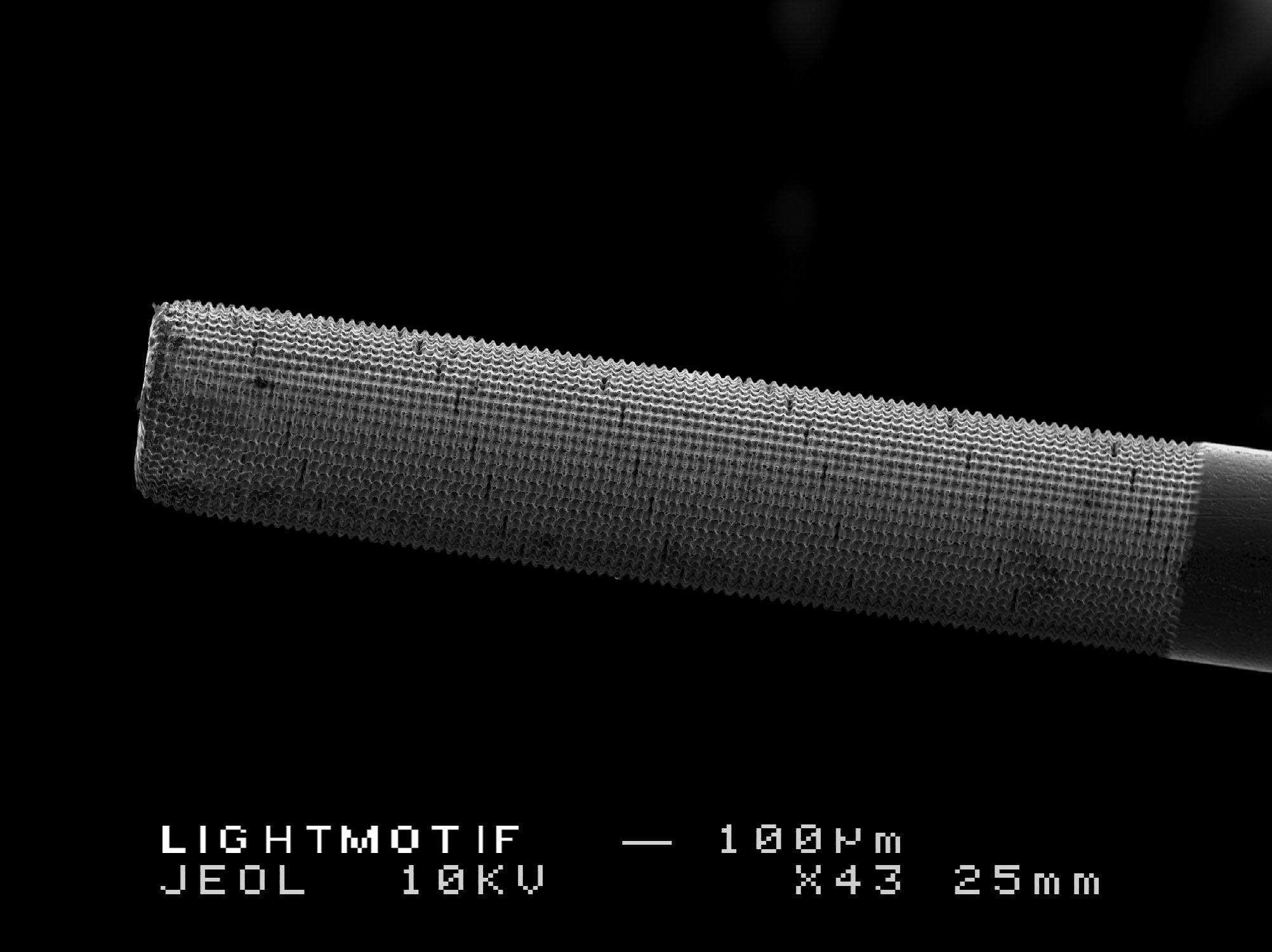

micro-milling

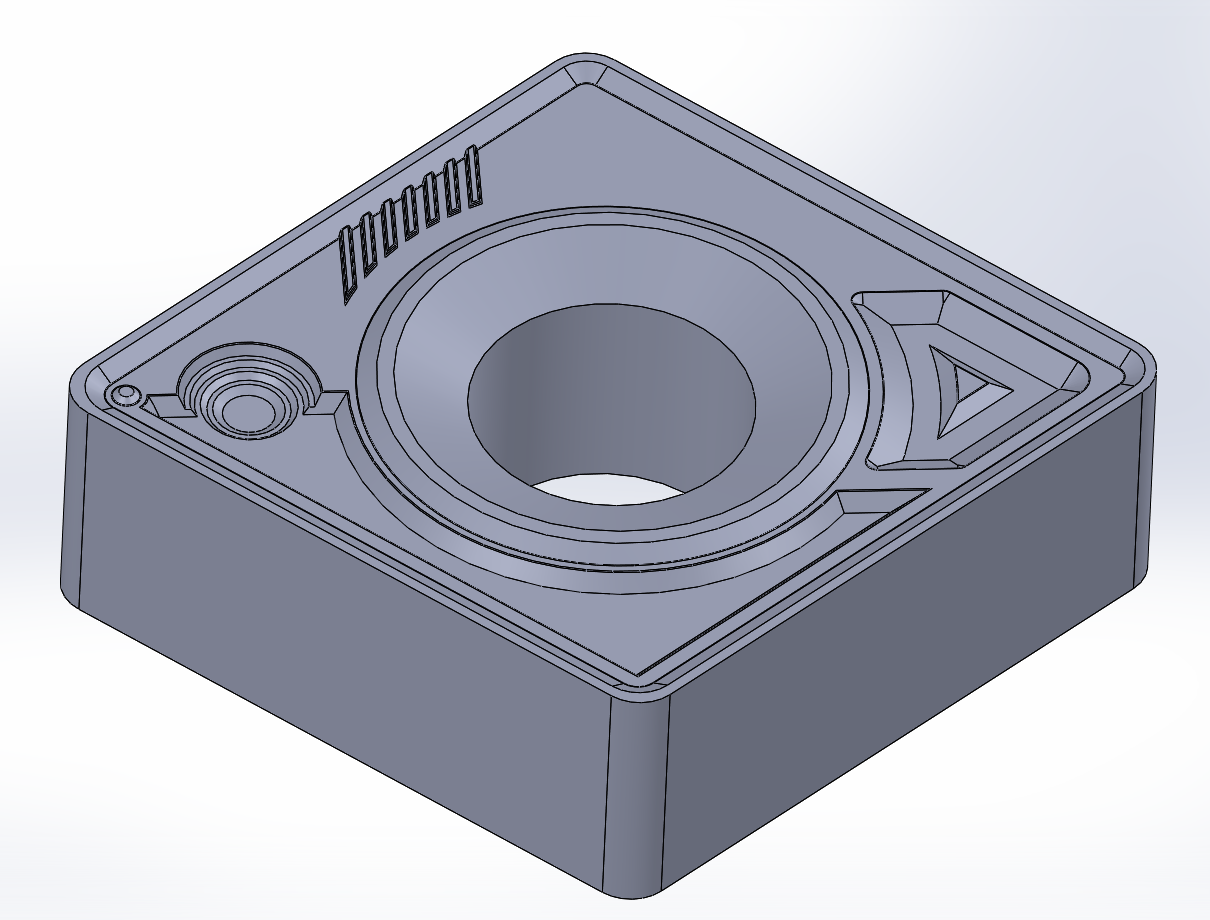

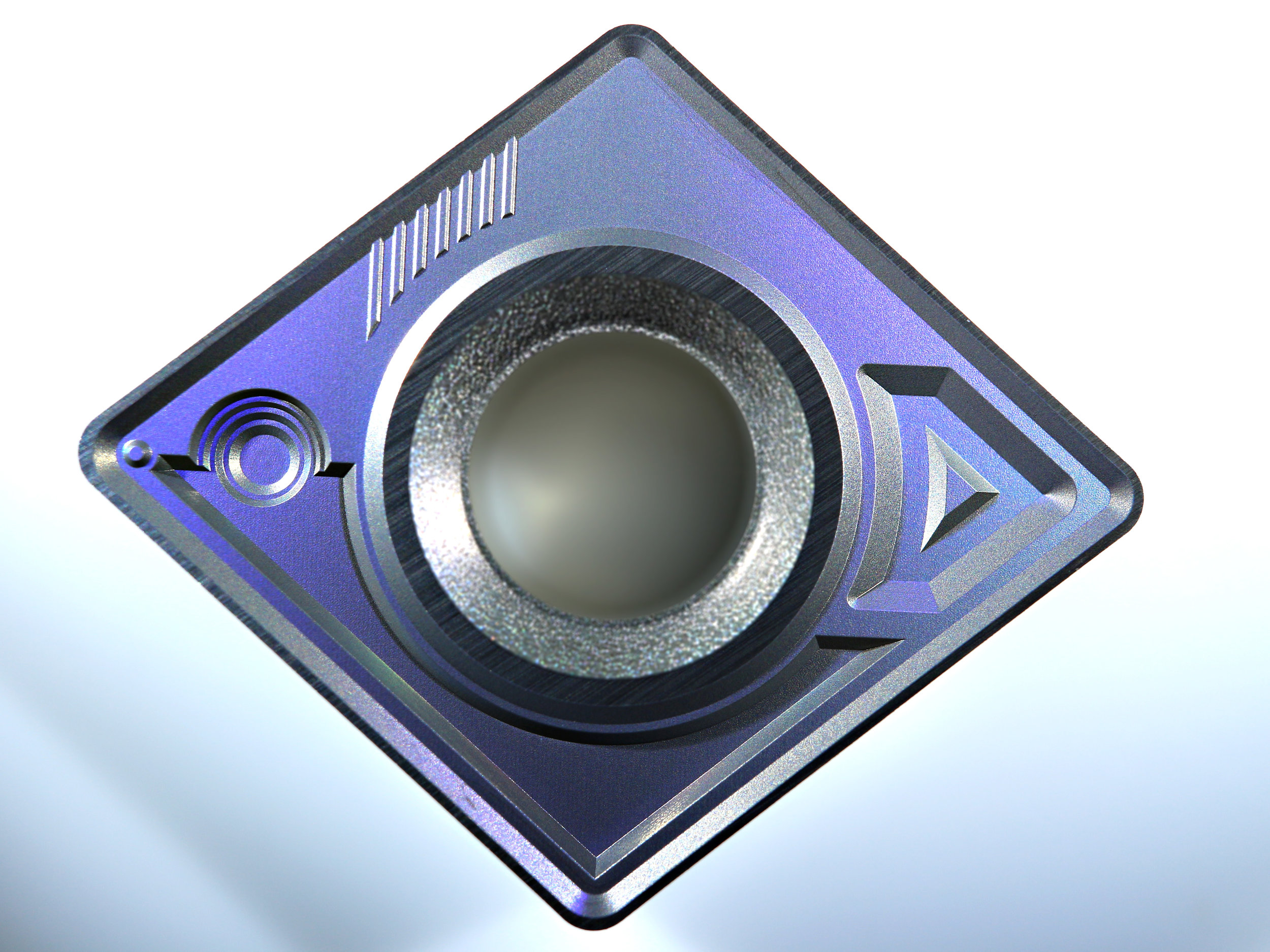

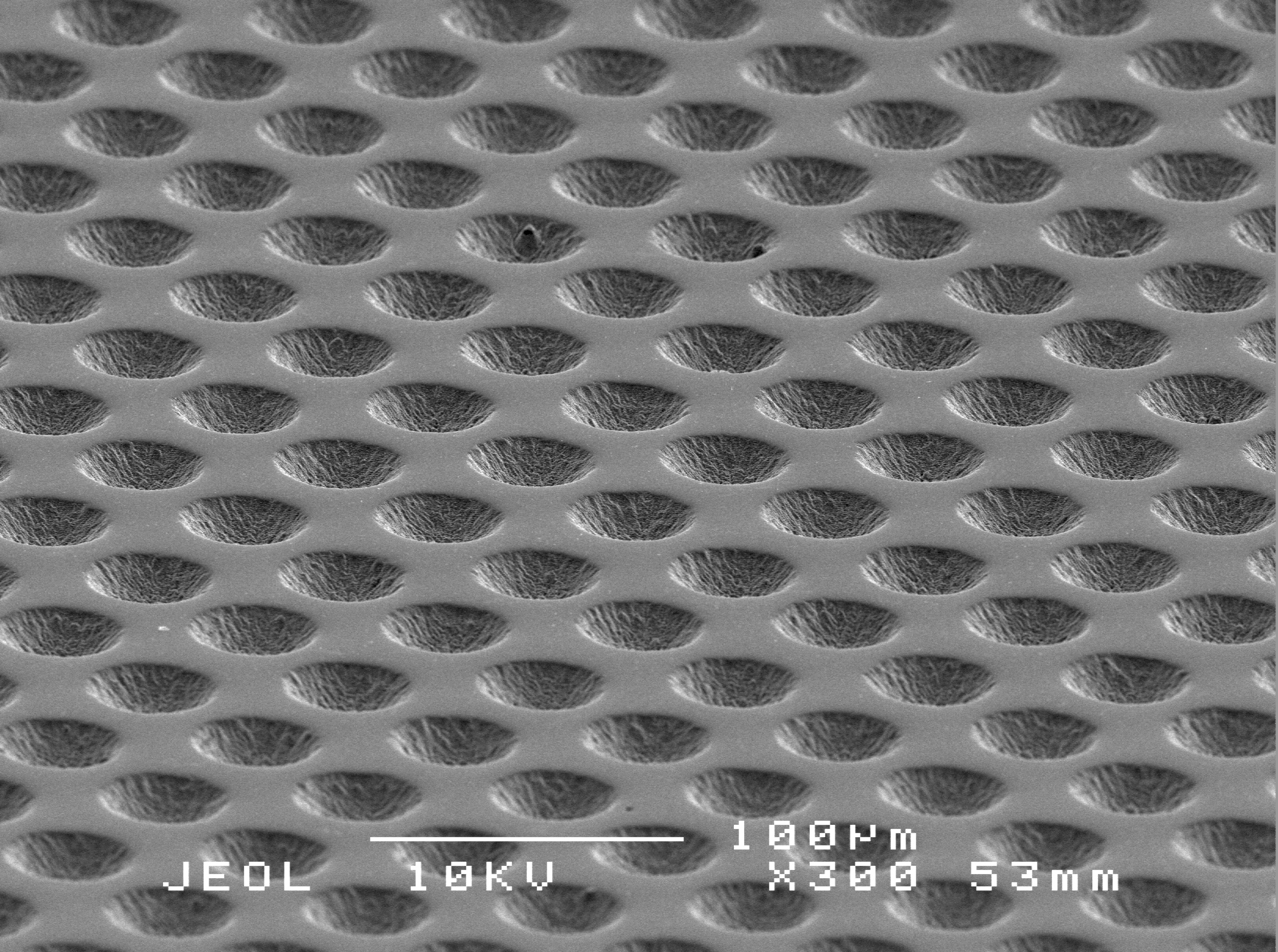

Laser micro-milling using ultrashort pulse lasers makes it possible to machine accurately shaped structures with very small features into nearly any material. The process allows removal of extremely thin layers and is especially interesting for machining of very hard materials and delicate parts.

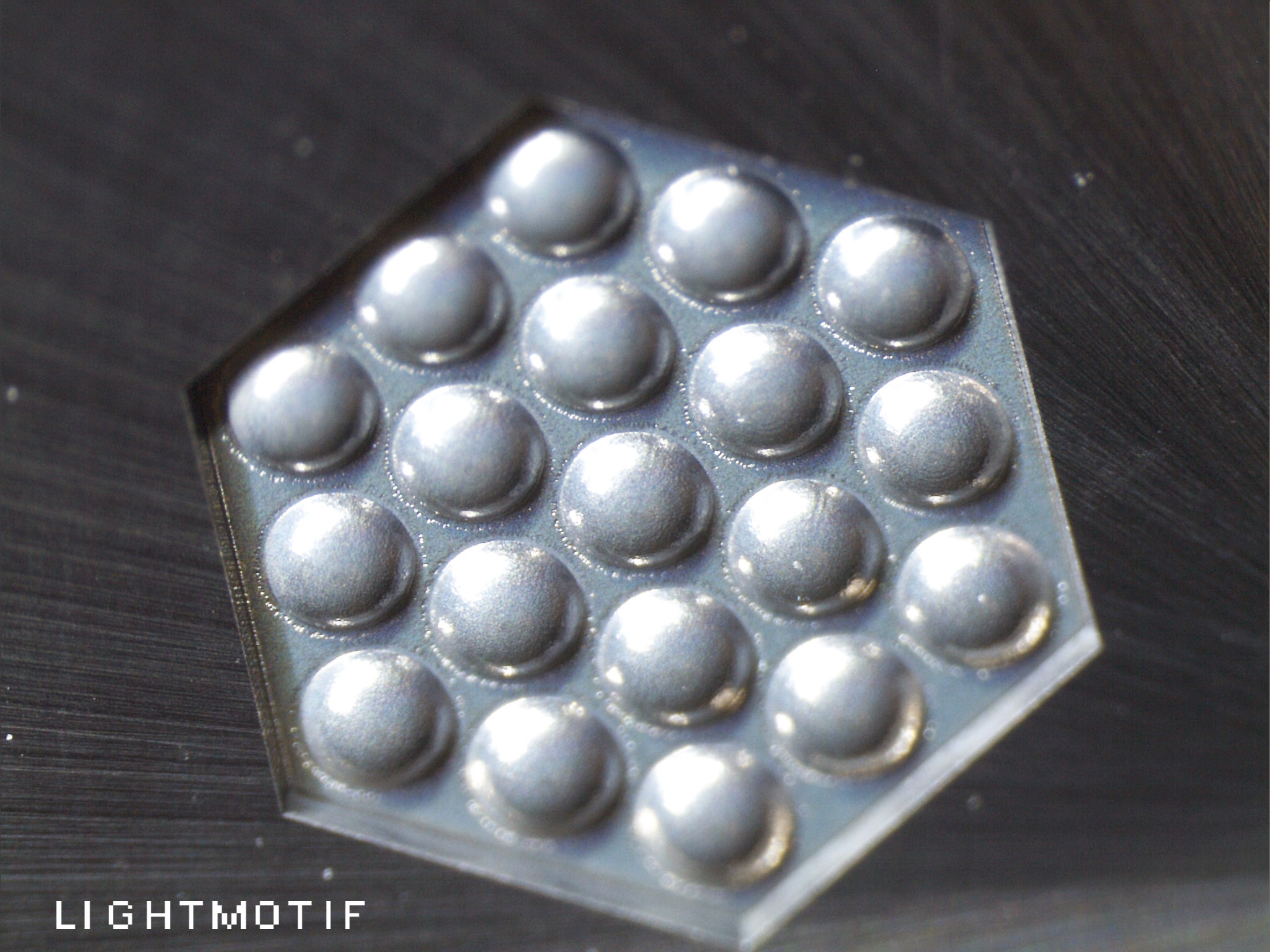

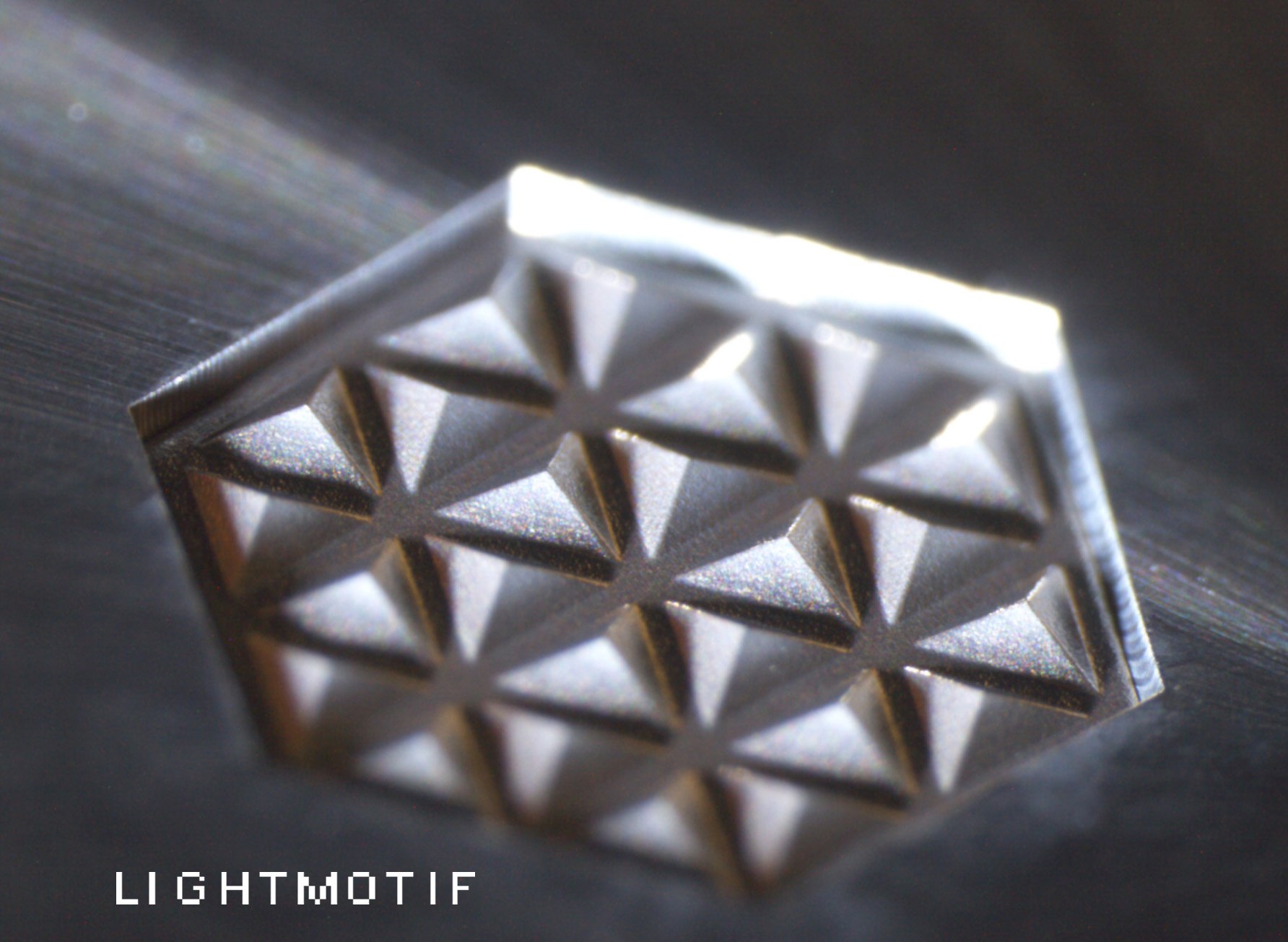

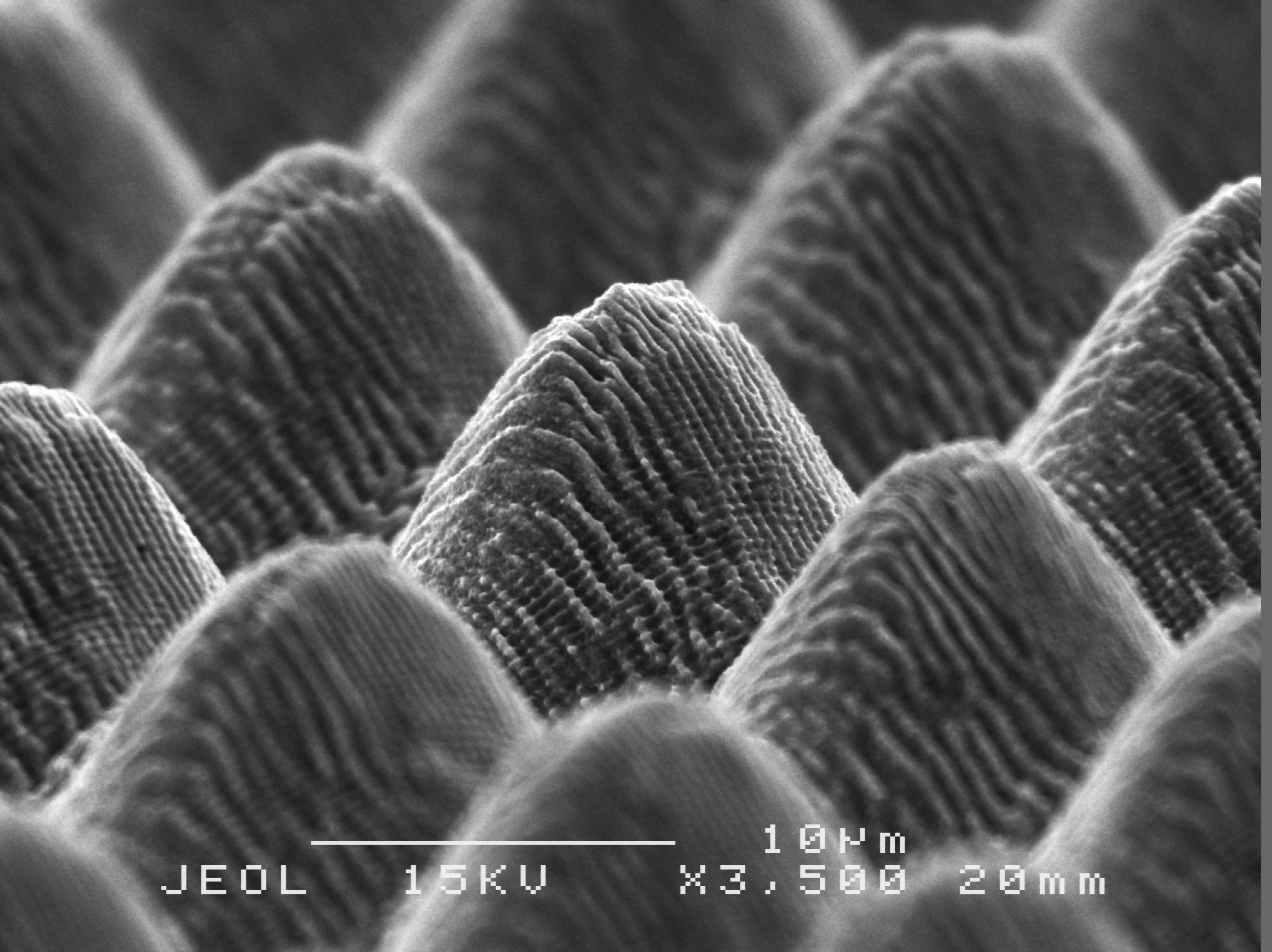

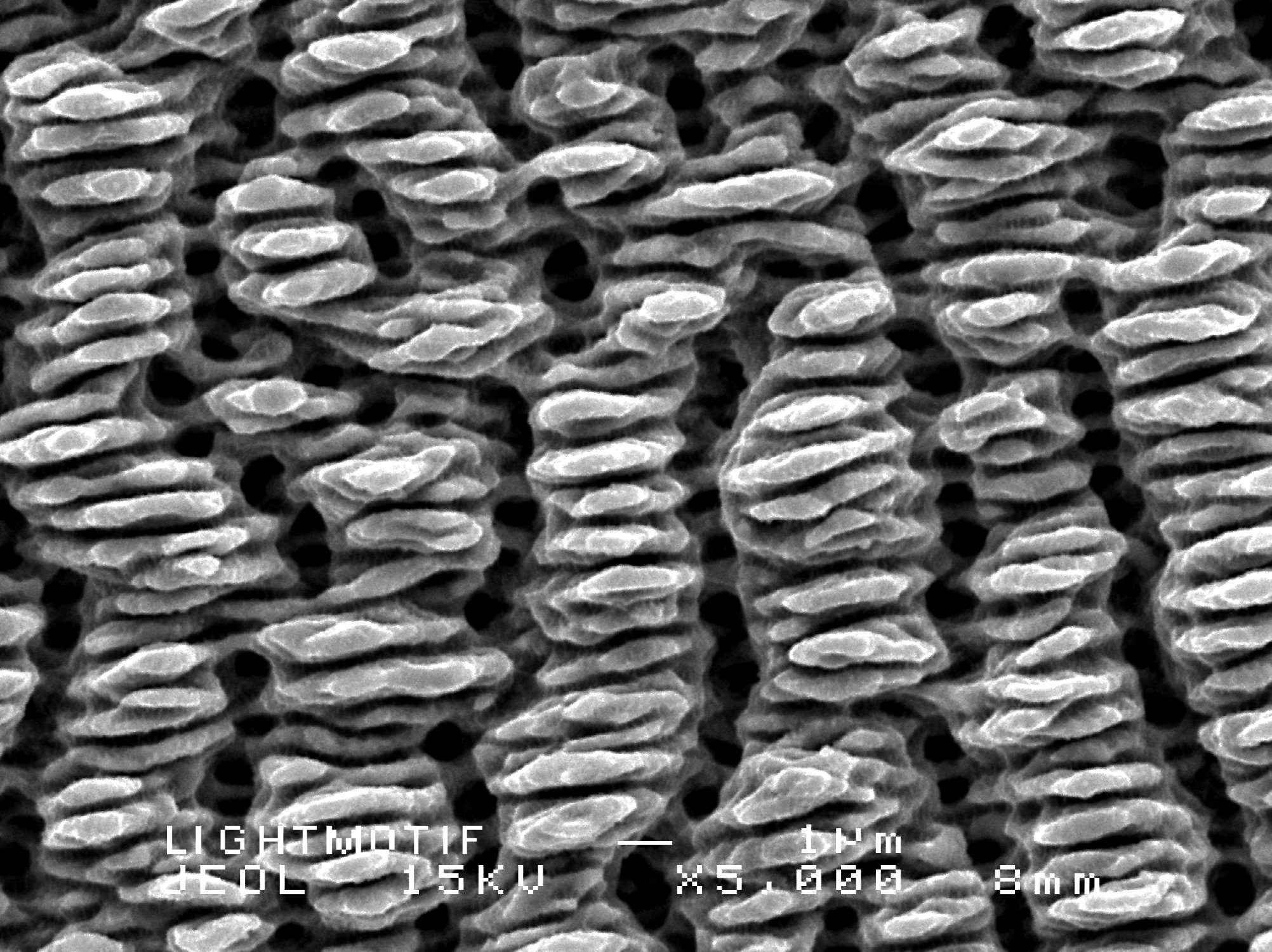

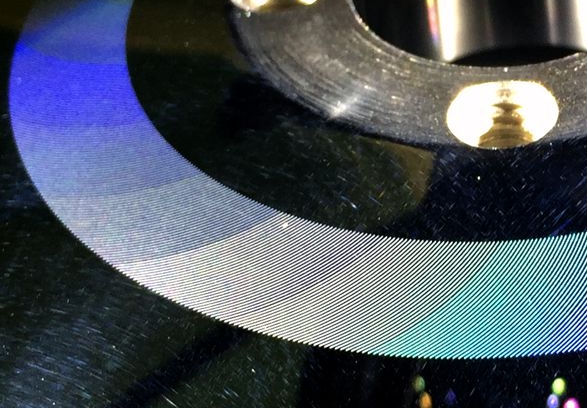

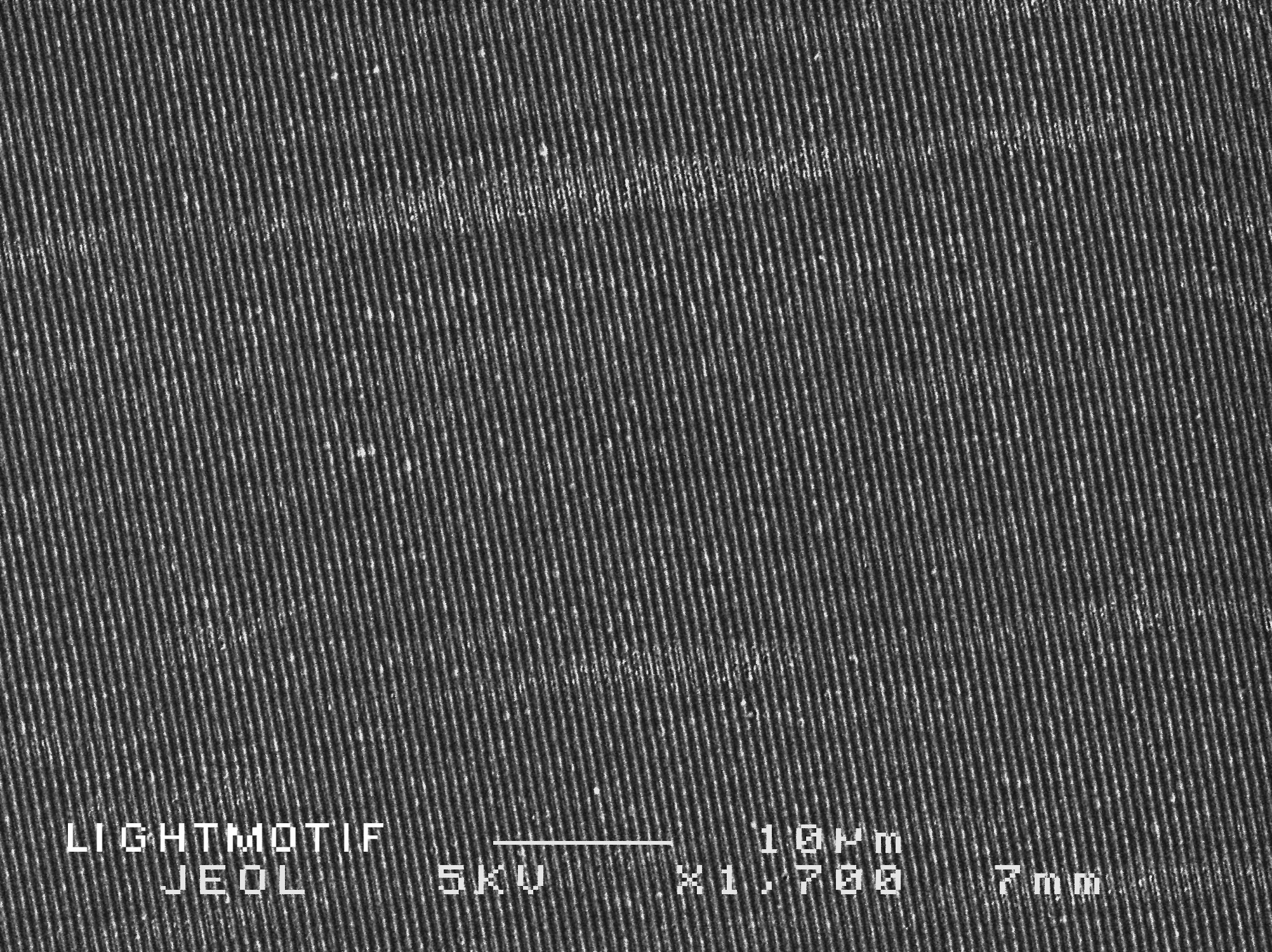

Surface texturing

Laser micro-texturing using ultrashort pulse lasers is a new technology for applying surface textures with very fine features and an extremely high depth resolution. It allows the creation of small-scale textures that change the functional properties of surfaces, like reduction of friction or change of optical properties. The process can be applied on any material and can be used for texturing complex curved surfaces.